VISCOBIT is a viscosity modifying organic additive for the production of warm mix asphalt (WMA). VISCOBIT is based on polyethylene wax. It can be used in mastic asphalt as well as rolled asphalt. It is suitable for the production of ready-to-use binders (including PMB) and for the direct use in asphalt mixing plants or cookers.

Our test series have shown that VISCOBIT, thanks to its special molecular structure, has no negative influence to the low temperature behaviour of warm mix asphalt.

VISCOBIT meets all requirements for a viscosity-modifying organic additive for warm mix asphalts.

This means the following advantages for the application:

Fraaß breaking point, ductility, plasticity range

Deformation (DSR, MSCR)

Cold temperature behavior (BBR)

ageing (RTFOT and PAV)

Reduction of normative compaction temperature

Cold temperature behavior: Indirect Tensile Strength tests (ITS) at -5°C, Cooling test (TSRST)

Fatigue behavior: Monoaxial pulsating tensile test

Mastic asphalt: German high way A3 (500m), Mastic asphalt 8 S, Binder: 25/35 VL (with 3% VISCOBIT)

Rolled asphalt: motorway feeder road to BAB 38: 600 m on L178 near Frankleben/Sachsen-Anhalt (Germany), asphalt surface course: AC 11 DS, binder: PMB 25/55-55 A (with 3% VISCOBIT)

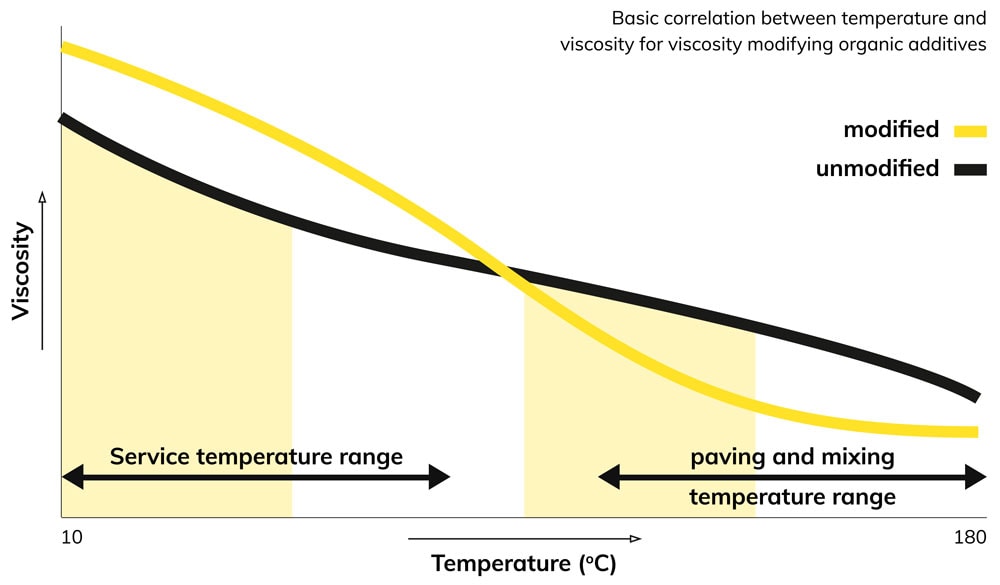

VISCOBIT has a specific molecular structure, which provides a good interconnection of the additive with the bitumen matrix. In opposite to some other viscosity modifying additives the cold temperature behaviour is therefore not impaired by VISCOBIT. With VISCOBIT, users achieve an increased plasticity range in the bitumen, especially in the direction of low temperatures.

The dosage of VISCOBIT depends on the quality of the used bitumen and the intended effects. Typically, the recommended dosage is between 2% and 3% related to Bitumen.

Yes, VISCOBIT can also be used in polymer modified bitumen. It is well compatible with bitumen, but also with the commonly used polymers and has a positive effect to polymer distribution and storage stability.

VISCOBIT is supplied either as free-flowing, dust-free fine grain with a medium particle size of approx. 0.5 mm or as granulate with approx. 4-8 mm grain size. To bring the product into the mixing equipment, pneumatic conveying systems or suction weighing systems are suitable.

VISCOBIT should be stored dry in its original packaging at room temperature. Direct exposure to sunlight and water should be avoided. When stored according to this recommendation, VISCOBIT has no limited shelf life.

Yes, it’s called Viscobit AdPro and it’s a new bitumen additive based on a modified polyethylene wax. It has a particularly good performance in improving deformation resistance, but additionally it has a positive influence to the adhesion to aggregates. It is also suitable for PMB.

Please contact us. We will get back to you shortly by e-mail.

Ethylen is our base product. Our products are polymerised under high pressure at about 2,000 bar. We manufacture waxes and other specialised products such as cold flow improver for freezing temperatures.

Since 2004 Innospec Leuna belongs to the globally active Innospec Group, which is focussed on chemical additives for a wide range of applications. In Leuna we achieve a turnover of approx. 50 M. €, with 110 highly motivated employees. Our customers benefit from our high flexibility, high quality standards, individual oriented- application consultation as well as competitive conditions.

Test our product. After submitting your request, we will promptly send a product sample to you.

… is a new bitumen additive based on a modified polyethylene wax. It has a particularly good performance in improving deformation resistance, but additionally it has a positive influence to the adhesion to aggregates. It is also suitable for PMB.